In the modern construction landscape, sustainability isn't just a buzzword—it's a necessity. As the industry struggles with environmental challenges, adopting green building practices becomes necessary for long-term success. We delve into actionable...

What the increase in Material Prices means to you

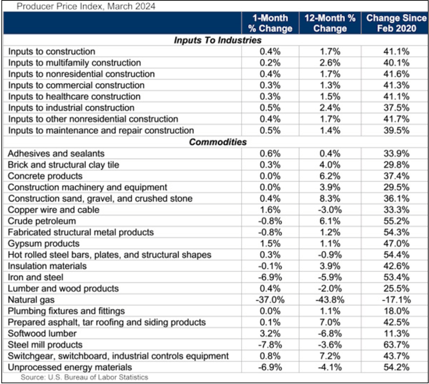

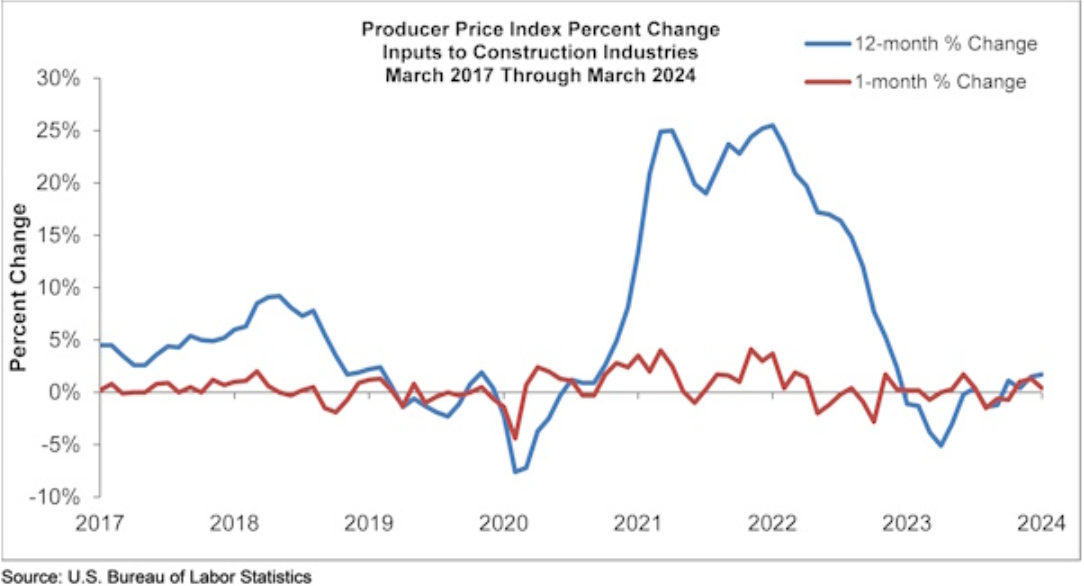

Although the year started with cautious optimism that costs would continue to go down, the latest data from the U.S. Bureau of Labor Statistics show an increase in construction input prices. Specifically, "construction materials prices increased 0.4% in March."

“There has been growing evidence of resurfacing inflationary pressures in the nation’s nonresidential construction segment during the past two months,” said ABC Chief Economist Anirban Basu.

“This is not especially good news for those who purchase construction services,” continues Basu. “In addition to supply chain issues, there is an abundance of publicly and privately financed megaprojects around the nation, massively increasing demand for certain inputs, and a majority of contractors expect their sales to increase over the next six months, according to ABC’s Construction Confidence Index. With continuing wage pressures and elevated borrowing costs, the implication is that financing construction projects will remain expensive relative to historic norms for the foreseeable future.”

This increase poses several implications for small to medium-sized specialty contractors. Here’s an analysis of what these changes could mean for such businesses and you:

Impact on Operating Costs

The 0.4% rise in input prices last month directly translates to higher operating costs for specialty contractors, which often operate with tighter margins and less financial flexibility compared to larger firms. As such, any increase in the cost of materials like steel, concrete, and even piping, wire, etc. can significantly affect profitability. Smaller contractors may need to reassess their current projects and future bids to accommodate these higher costs.

For Capital Electric, the advantages of new technology streamlined their operational efficiency. Financially, the “quote comparison feature [in StructShare’s tool] proved invaluable, bringing about at least a 10% reduction in material costs.” (Read their full story)

Challenges in Pricing and Bidding

For specialty contractors, accurately pricing services becomes more challenging in an environment of rising input costs. The need to adjust quotes to reflect increased material costs can make their bids less competitive, particularly if larger competitors with more purchasing power can negotiate better deals with suppliers. This situation may result in smaller firms losing out on contracts, especially in competitive bidding scenarios.

Kraun Electric’s experience with (new technology such as) StructShare showcases the transformative power of the right digital procurement solution. The shift from a fragmented and inefficient process to a streamlined, centralized system has not only saved time and reduced errors but also fostered better relationships with suppliers. (Read their full story)

Cash Flow Constraints

Higher input prices can strain the cash flows of small to medium-sized contractors. Purchasing materials at higher prices requires more capital up front, potentially leading to cash flow issues, especially if payments from clients are delayed. This can affect the ability to take on new projects or even continue with ongoing ones without financial stress.

Strategic Adjustments

To mitigate these challenges, specialty contractors might need to make several strategic adjustments:

- Negotiating with suppliers: Developing stronger relationships with suppliers to secure better prices or favorable payment terms could be crucial.

- Improving efficiency: Implementing more efficient construction techniques and better project management practices to reduce waste and lower overall project costs.

- Diversifying suppliers: Exploring alternative suppliers or materials that might offer cost advantages.

- Adjusting service offerings: Considering niche markets or specialized services that might command higher margins or are less affected by material cost fluctuations.

Long-term Implications

If the trend of rising input costs continues, it could reshape the competitive landscape in the construction industry. Smaller contractors might need to specialize further or merge with other firms to leverage collective bargaining power and resources; moreover, this environment could accelerate innovation in construction techniques and the adoption of new technologies, such as StructShare, that improve efficiency and reduce reliance on traditional ways of purchasing and managing materials.

In conclusion, while rising construction input prices present challenges, they also push specialty contractors to adapt and innovate. Those who can manage their costs effectively and remain flexible in their operations are more likely to thrive despite these economic pressures. We welcome you to request a 25-minute demo of StructShare.

Get the latest insights on materials management for modern construction jobsites.

Green Building Success: Sustainable Strategies for Construction

by Lexi Garden | Mar 14, 2024 | Trades 101 Blog, News, Material procurement, Materials Management, Construction material management, Materials Procurement, Trades Blog

7 Reasons Technology Drives Successful Projects

by Christian Erickson | Feb 28, 2024 | Trades 101 Blog, News, Material procurement, Materials Procurement, Trades Blog

Specialty trade contractors face unique challenges in purchasing and material management that often go beyond the capabilities of basic tools like email, text, and spreadsheets. Learn why embracing more advanced tools is essential for successful projects and...

Revolutionizing MEP Procurement: StructShare’s Out-of-the-Box Catalog

by Christian Erickson | Feb 7, 2024 | Trades 101 Blog, News, Materials Procurement, Trades Blog

This release is a testament to our commitment to staying ahead in the industry. By continuously developing, StructShare demonstrates our understanding of the evolving needs of construction professionals. For MEP trade contractors and construction...